Emergency Stop Description

Operating the EMERGENCY STOPThe EMERGENCY STOP should be operated in the following situations:

"EMERGENCY STOP" must not be used for production breaks or to switch off the machine. When EMERGENCY STOP is pressed:

CAUTION - Risk of tool breakage. If an EMERGENCY STOP is pressed during machining, there is a risk of tool breakage. Activating the EMERGENCY STOPActivating the EMERGENCY STOP function will stop the machine as fast as possible. Damage of the workpiece and tools may occur.

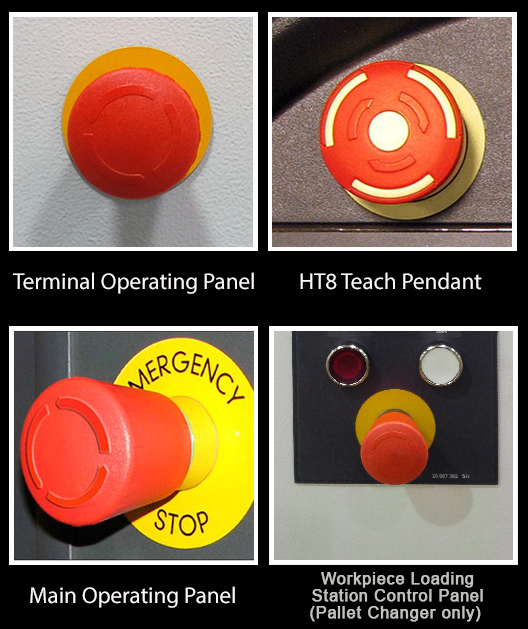

Unlock EMERGENCY STOP facilityEMERGENCY STOP buttons are unlocked by turning them to the left (HMI) or right (HT 8) as indicated by the directional arrows embossed on the face of the pushbutton. Unlocking the EMERGENCY STOP device will not cause the machine to be restarted automatically. CAUTION - The function of the EMERGENCY STOP facility must be tested manually every 1000 hours! |